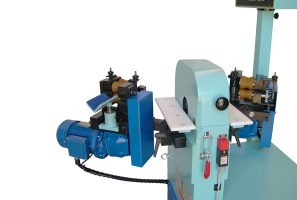

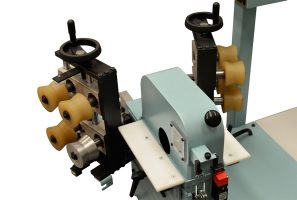

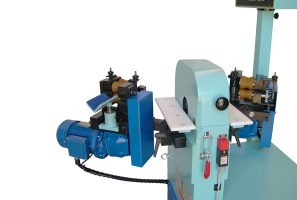

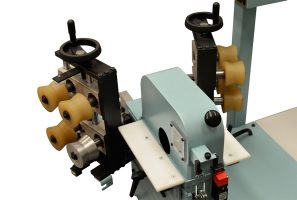

AV SELFCENTERING feed with adjustable spped through inverter device for strainght and TAPER PARTS max diameter 45 mm

AV SELFCENTERING feed with adjustable spped through inverter device for strainght and TAPER PARTS max diameter 45 mm (hinged for “manual” feed processing)

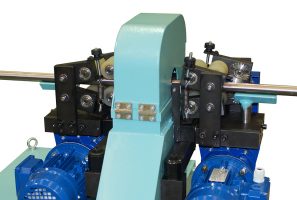

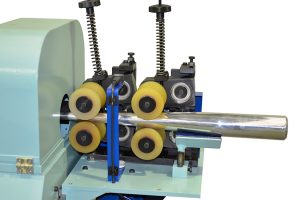

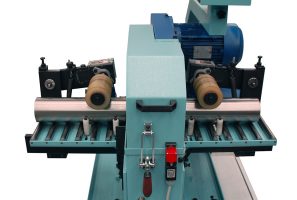

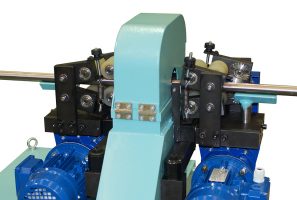

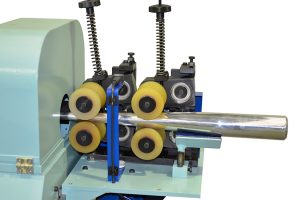

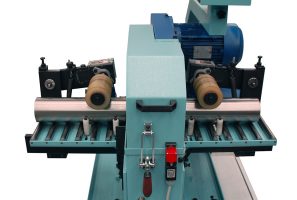

ADN automatic self centering feed system for straight tubes with 4+4 rollers (Not for taper parts) with adjustable feed trough inverter

ADN automatic self centering feed system for straight tubes with 4+4 rollers (Not for taper parts) with adjustable feed trough inverter (Hinged, for manual feed processing)

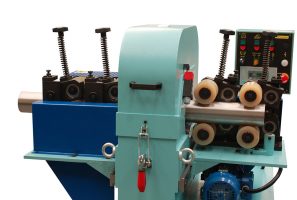

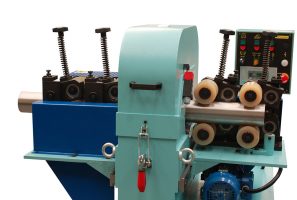

ALT SELFCENTERING automatic feed for straight and cylindrical TAPER PARTS and adjustable feed with inverter

ALT SELFCENTERING automatic feed for straight and cylindrical TAPER PARTS and adjustable feed with inverter

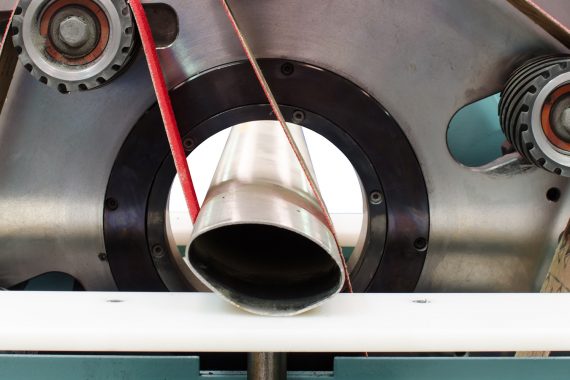

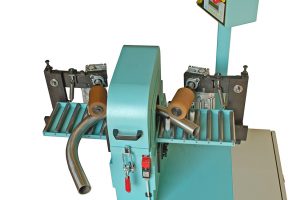

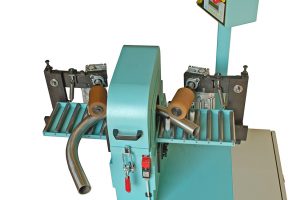

AVU “UNIVERSAL” feed for both straight and bent parts with adjustable speed through inverter

AVU “UNIVERSAL” feed for both straight and bent parts with adjustable speed through inverter

AN foot pedal equipment for a easier workpiece insert betwenn the abravive belts

AN/A equipment for automatic opening and close of the abrasive belts through photoeye and in/out timers

Abrasive belts speed adjustable (10-30 mt/sec) with inverter and digital display with mt/sec real values

Controls panel with digital display for belts speed and feed system speed adjusting.

Touch-Screen controls panel for working cycles programming, feed rate adjustment