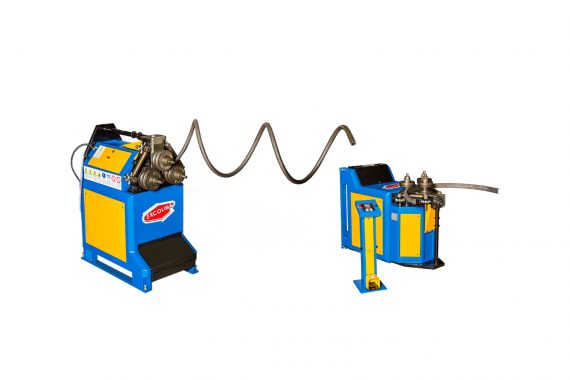

General information

CE40H3 is one of the most demanded Ercolina ring rollers that has all the advantages of true European profile bending machine. Its heavy and robust structure guarantee reliability and long-lasting high-level performance with all applications. CE40H3 has 40 mm forged steel shafts, hydraulic upper roll with patented descent system that minimizes profile deformation. The machine comes with standard set of rolls intended for square and rectangular profile bending. CE40H3 has three driven rolls but the machine is also available in simplier CE40H2 version.

Models available:

- CE40H3 – hydraulic, three driven rolls

- CE40H3V2 – hydraulic, three driven rolls, two speeds

- CE40H2 – hydraulic, two driven rolls

- CE40H2V2 – hydraulic, two driven rolls, two speeds

Features

- Universal roller set included with each machine

- Nickel-chromium steel shafts forged, treated and ground for maximum performance with minimum bending

- Heavy and robust machine body with very rigid parts for high repeatability

- Ercolina patented top roller descent system that minimizes profile deformation

- Controls with programmable touchpad and digital readout of central roller positioning

- Up to eight (8) programs and unlimited steps can be stored

- Threaded shafts equipped with micrometric adjustment ring nut for the correct and easy positioning of the tools; the use of additional spacers is not normally required

- Direct shaft guiding system

- Upon request available the lateral anti-twist/anti-twist rail system for inner wing corner profiles

- 2-speed model available

Technical data

| Roll Shaft Diameter | 40 mm |

| Standard Roll Diameter | 165 mm |

| Max Center Roll Stroke | 124 mm |

| Roll Shaft Speed | 10 rpm / 10-20 rpm (mod. V2 60Hz) |

| Independent Drive Rolls | 3 smooth |

| Voltage | 220 / 240 – 380 / 440 V |

| Motors | 1,85 kW |

| Hydraulic Motor Power | 1,50 kW |

| Machine Mainframe | Cast Iron GS500 |

| Piston Force | 114 000 N |

| Machine Operating Position | Horizontal and Vertical |

| Setting of the upper roll | Hydraulic |

| Display | Digital |

| Machine Body Construction | Weldel Steel |

| Number of Programs | 8 |

| Electric foot Pedal control | Yes |

| Dimensions LxLxH | 560 x 1430 x 980 mm |

| Weight | 430 kg |

Maximum capacity

| Section | Dimensions (mm) | Ø min. (mm) |

|---|---|---|

| 2 ” Gas x 3,2 | 450 | |

| 70 x 1,5 | 700 | |

| 50 x 50 x 3 | 500 | |

| 35 | 250 | |

| 35 x 35 | 250 | |

| 50 x 50 x 6 | 300 | |

| 60 x 60 x 6 | 400 | |

| 80 x 45 x 6 | 350 |